No products in the cart.

Hiển thị 65–80 của 160 kết quả

Our DC drives for use with SCR rated motors. Models range from sub-FHP through 3 HP. NEMA® 1, NEMA 4/12 and NEMA 4X enclosures available. Low voltage controls available through 120 amps @12/24 V and 100 amps @ 36/48 V

Draft inducer blowers are original equipment manufacturer (OEM) replacements used in furnaces and water heaters. They are a shaded pole or permanent split capacitor (PSC) motor-driven small blower wheel assembly and come in 3 3/8 diameter with fan and blower capability.

The Fasco® brand still leads the industry in direct replacement draft inducers.

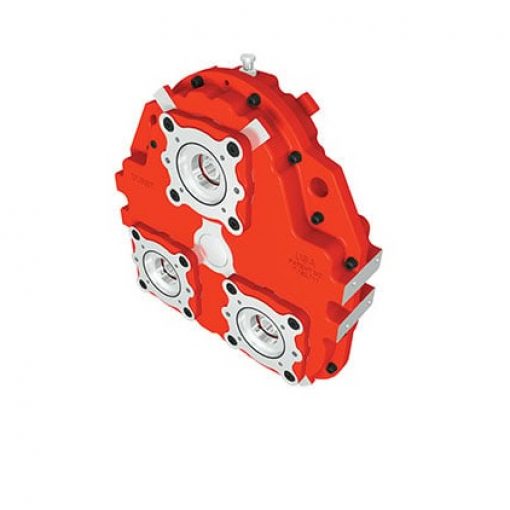

Durst® Pump Drives is a leading modular design hydraulic pump drive solution that can be easily configured to meet your application needs. Our patented pump pad design keeps oil flowing through the bearing.

EC centrifugal fans, equipped with electronically commutated brushless DC motors, offer energy-efficient and precise air movement for diverse applications, from HVAC systems to industrial processes. Their compact size and adaptable speed control ensure optimized airflow while reducing energy consumption. Choose these fans for effective and sustainable ventilation and cooling solutions.

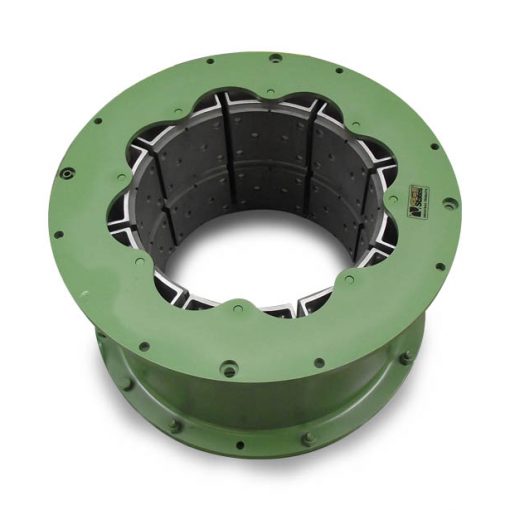

Designed for high-horsepower hydraulic fracturing applications.

An economical solution to meet the demands of greener, next generation fracking processes.

Ameridrives engineers have developed a new U-joint based on the proven design of the popular Ameridrives U3315 model. The economical shaft, with a peak torque rating of 1,100,000 lb.in., can handle the environmentally-friendly, higher horsepower diesel engine and gas turbine drives being utilized on newer trailer- mounted pump packages.

The Ameridrives team of highly experienced application and U Joint engineers is always available to design a modified solution to meet specific customer requirements.

Shaft guards help protect workers from rotating hazards and help protect rotating equipment from external and environmental damage.

Falk Lifelign gear couplings are well-suited for general industrial applications. Triple-crowned teeth minimize wear caused by misalignment. By eliminating tip-loading while reducing backlash and radial clearances, Lifelign can help protect connected equipment from damaging loads.

The True Torque system uses a mechanical release mechanism that disengages the coupling when the torque limit is exceeded, preventing damage to the equipment and minimizing downtime. The disengagement torque is adjustable and can be set to match the specific requirements of the application. The Falk True Torque coupling is a reliable and cost-effective solution for protecting valuable equipment from damage caused by torque overload.

Built for longer service life with an integral high-speed pinion, fully supported by bearings within the gearbox. Ultramite is motor-independant allowing the use of standard NEMA C-face or IEC motors.

The gear drive that delivers reliability, keeps maintenance costs down, maximizes uptime and utilizes the latest technology; the Falk V-Class outperforms and outlasts the competition.

Designed for improved strength and performance and precision manufactured, Y Unit Gear Drives transmit at higher capacities up to 10,000 hp (and 2.8 million lb-in output torque), without increasing the housing size.

Electronically Commutated Motor (ECM) or shaded pole fan packs are ideal for retrofit or replacement of original equipment manufacturer (OEM) fan packs and commercial refrigeration evaporator units. The new innovative design of the KRYO™ Fortress fan pack is water-tight, dust-tight and submersible, giving it a remarkable IP66 and IP67 rating. Features include 2-pin molded plug and long-life ball bearing design.

- Fertilizer plant: gas turbine to compressor, 23,767 hp (17,730 kW) at 10,973 rpm

- Floating production, storage and off-loading (FPSO) ship: gas turbine to generator, 30,161 hp (22,500 kW) at 13,192 rpm

- Liquefied natural gas (LNG) upstream facility: gas turbine to gearbox, 18,633 hp (13,900 kW) at 9,500 rpm

Gearmotors (geared motors) are made up of a gearing and motor packages designed together and engineered for durability and reliability. Gearmotors come in a range of shaft, torque, and speed requirements for any operation.