No products in the cart.

Hiển thị 49–64 của 174 kết quả

CENTAFLEX-K/KE/KF series is a coupling with high torsional stiffness and resonance-free operation. Ideally suited for hydrostatic driven construction equipment, lower-horsepower applications are easily handled by the CENTAFLEX-K/KE/KF series. Built from shock-resistant glass-fiber reinforced plastic, the CENTAFLEX-K/KE/KF is highly robust with an axially short design. The series features blind assembly to minimize mounting effort requirements. Delivered with a flywheel connections according to SAE, the CENTAFLEX-K/KE/ KF is available with standard spline or the CENTALOC spline clamping hub to eliminate fretting corrosion and is also available for non-standard flywheels.

CENTAFLEX-A constant velocity driveshafts are available in various lengths to adapt to your needs and installation requirements. The highly flexible CENTAFLEX-A driveshafts are particularly well suited for use in marine, industrial, energy, and rail applications. The CENTAFLEX-A is a high-performer with high torsional elasticity. Built to damp torsional vibrations and shock loads, the CENTAFLEX-A element can compensate considerable axial, radial, and angular misalignments. Available in thin wall steel tube, carbon-fiber or glass-fiber designs, and with a split element option, the CENTAFLEX-A is easy to install and maintain with minimum effort. The electrically-insulating and thermally-resistant silicone element option offers a reliable, fail-safe, backlash-free transmission of high torques where needed.

Flexible elements for CENTAFLEX-A Type 0 couplings.

Flexible elements for CENTAFLEX-A Type 0-S couplings.

CENTAFLEX-ACV is a highly flexible constant velocity driveshaft, ideal for the connection of marine gear output flanges to propeller shafts, and for applications with considerable angular deflections. The CENTAFLEX-ACV offers torque transmission via a double cardan driveshaft featuring a CV joint on one side and a highly flexible rubber element on the other. Ideal for marine use, a self-aligning thrust bearing transmits propeller thrust to the boat hull. Specifically designed to reduce noise, vibration, and shock, the CENTAFLEX-ACV damps torsional vibrations while offering electrical insulation as well. The CENTAFLEX-ACV tolerates angular deflections of up to 3 degrees. This driveshaft is easy to install and can be mounted with minimal effort thanks to the easy-to-use clamping hub.

CENTAFLEX-AGM is a highly flexible constant velocity driveshaft ideal for connecting marine gear output flanges to propeller shafts in applications with moderate angular deflections. The CENTAFLEX-AGM offers backlash-free torque transmission with a double cardanic driveshaft, featuring two-highly flexible rubber elements. Ideal for marine use, propeller thrust is transmitted to the boat hull by a self-aligning thrust bearing. The CENTAFLEX-AGM is designed to reduce noise and minimize vibrations, ensuring less wear and tear on surrounding equipment. Built to damp torsional vibrations and shock loads, the CENTAFLEX-AGM tolerates angular deflections of up to 3 degrees. Additionally, the CENTAFLEX-AGM driveshaft offers a significant degree of electrical insulation. The driveshaft can be mounted with minimal effort using the clamping hub. Installation and maintenance are simple, and the product is delivered ready to install.

CENTAFLEX-AM is a highly flexible coupling, built for connecting marine gear output flanges with a propeller shaft, while isolating the boat hull from noise and vibration. The CENTAFLEX-AM provides backlash-free transmission of torque and propeller thrust using a highly flexible rubber element and thrust bearing. This coupling is specifically designed to reduce noise and vibrations, prolonging the life of surrounding equipment. The flexible coupling damps torsional vibrations and shock loads while offering a high degree of electrical insulation. Designed to compensate moderate axial, radial, and angular misalignments – a common cause of wear – the CENTAFLEX-AM is available in a wide range of standard sizes covering engine power up to several hundred kW. Easily mounted with a clamping hub, the CENTAFLEX-AM is delivered ready to install.

CENTAFLEX-M is a highly flexible CENTAFLEX coupling designed to connect gear output flanges to a propeller shaft, specifically in applications where mounting space is limited. Featuring a highly flexible rubber element, the CENTAFLEX-M offers backlash-free transmission of torque and propeller thrust. Designed to reduce noise and vibration under small and confined spaces, the CENTAFLEX-M damps torsional vibrations and shocks while limiting structural noise and providing significant electrical insulation. Built compact, the CENTAFLEX-M reduces handling and maintenance costs by omitting the additional components typically needed, like spacers. The CENTAFLEX-M compensates axial, radial, and angular misalignments for added safety and reduced wear and tear. Easy to mount by using the clamping hub, the CENTAFLEX-M is an ideal solution for limited mounting spaces.

The CENTAMAX-B is specially designed for well aligned independently-mounted generator sets and free-mounted drives, offering backlash-free transmission of medium torques. The fail-safe design of the CENTAMAX-B is characterized by a high torsional flexibility to damp torsional vibrations and minimize shock. The CENTAMAX-B design compensates axial and angular misalignments. Precompressed radial pins are offered for easy mounting, and the CENTAMAX-B features simple radial replacement of rubber elements and a maintenance-free design. Available for SAE flywheel connections as well as non-standard flywheels and shaft-to-shaft connections. CENTAMAX-B is well suited for diesel-electric locomotive drives where the engine and generator may sit at an unloaded idle speed condition for long periods of time.

Request Information →The CENTAMAX-G was developed for torsionally-active generator and pump drives. Torque is transmitted to the rubber element through the interlocked outer flywheel flange. Available with CENTALAN-HT elastomer, a high-temperature tolerant, synthetic material developed to meet the dynamic characteristics of natural rubber mixtures. Characterized by high torsional flexibility with linear characteristics, the CENTAMAX-G couplings damp torsional vibrations and shock loads and compensate axial, radial, and angular misalignments. CENTAMAX-G is equipped with an industry standard taper-locking bushing for quick and easy installation. Available for engine and generator connections according to DIN-6281. The CENTAMAX-G is available with flywheel connections according to SAE and offers a plug-in version for easy assembly and mounting.

The CENTAMAX-HTC is optimized for higher allowable power loss for drives subject to extreme torsional vibration. The CENTAMAX-HTC enables torque transmission via a toothed outer ring onto a rubber-in-shear element divided into slim sections. The highly reliable design is axially compact yet ideal for high-torque applications. With optimized higher allowable energy loss due to increased surface area, improved heat dissipation, and more effective ventilation, the CENTAMAX-HTC is a robust coupling solution for modern low emission diesel engines. Available with CENTALAN-HT elastomer for superior heat-resistance. Built to damp torsional vibrations and shock loads, the CENTAMAX-HTC compensates significant axial, radial, and angular misalignments. The compact, economic design proves superior when compared to standard double element couplings, making this a high-performance solution. Available for SAE and non-standard flywheel connections, the CENTAMAX-HTC offers plug-in blind assembly and minimal mounting effort.

The CENTAMAX-S is a highly reliable rubber-in-shear solution for the transmission of high torques. Thanks to compact dimensions, the CENTAMAX-S is ideal for tight spaces. The CENTAMAX-S transmits torque to the rubber element through an interlocked, toothed outer ring. This offers reliable, high-torque transmission, a high torsional flexibility with linear characteristics. The CENTAMAX-S damps torsional vibrations and shock loads. Built to compensate axial, radial, and angular misalignments, the CENTAMAX-S coupling is also available with an oil-resistant silicone design option or CENTALAN-HT for improved heat resistance. Available plug-in version offers easy assembly and minimal mounting effort.

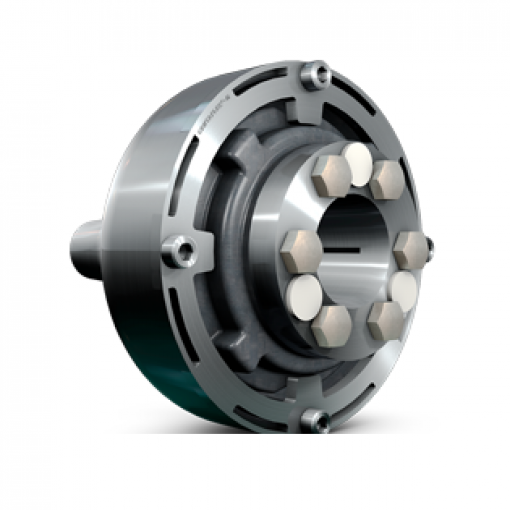

Built for diesel-driven compressor and pump drives, the CENTAX-K is a torsionally soft coupling based on a rubber-in-shear element vulcanized to a glass-fiber reinforced plastic flange. CENTAX-K’s reliable compensation of misalignments has been endurance-tested (type-tested), and proven. The CENTAX-K features a compact design and is available with a silicone elastomer for high-temperature applications. Plug-in features are available for simple equipment mounting. All standard flywheel connections are realized with the CENTAX-K for efficient, fast, and easily-customized solutions.

Under the CENTAX-K product line, the CENTAX-KK features a two-piece connection to the driven units. Using an additional hubstar from the CENTAFLEX-K series, an axial blind mount is achieved. The design allows for keyed connections, conical clamping, or the CENTALOC-clamping. The positive locking of the hub with an integrated rubber bumper provides additional innovation and customization, ensuring that the fixed rotating direction coupling is free of backlash. The innovative design ensures reduced noise during operation. Excellent for marine and energy applications, the CENTAX-KK has the quality features of the CENTAX-K, available customization, and superior adaptability for each application.

Part of the CENTAX-K line, the CENTAX-KS features a hub integrated into the plastic flange on the driven-side. The driving unit of this one-piece coupling is then plugged onto the splined shaft of your driven equipment for ease of assembly. The CENTAX-KS is available in variations to suit many different applications. Able to damp torsional vibrations and impacts to reduce wear and tear on your gear or pump, the CENTAX-KS compensates for axial and radial misalignment that may result during operation. The series covers torques ranging from 400 to 800 Nm. Tested and proven, CENTA products can withstand the toughest applications.

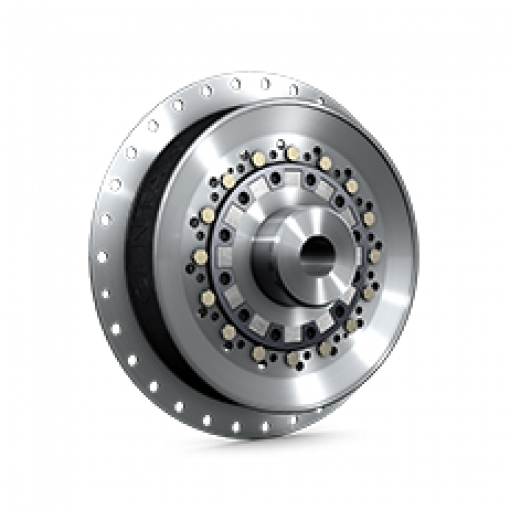

Ideal for heavy-duty and high-speed applications, the CENTAX-TT is a compact twin torque coupling with high performance. Designed with two concentrically arranged, pre-compressed “twin” rubber segments to jointly transmit torque, the CENTAX-TT is a high-performing design specifically built for a high torque range. Used for ship propulsion, generator sets, and similar applications, the CENTAX-TT is characterized by medium torsional stiffness. Torsional adaptation can be achieved by adjusting the number and arrangement of the rubber segments to allow for many different configurations. The CENTAX-TT damps torsional vibrations and shock loads. Able to compensate axial and radial misalignments, this flexible coupling is an ideal solution. Effectively ventilated for high admissible energy loss, the CENTAX-TT can hold up under many tough environments. Mounted with minimal effort and replaceable without movement of surrounding coupled components, the CENTAX-TT is a compact, low-maintenance coupling solution.